Structural Monitoring

Situation: At a petrochemical plant, periodic inspections are conducted to assess the condition of outdoor tank foundations, base connections and piping supports. Subjected to the elements, these structures may be located hundreds of feet from the main facility and out of range of the plant wi-fi network.

Solution: WISE-BACK™ provides a highly portable tool set—lightweight and carried on a belt—to facilities structural monitoring rounds. Photos taken with the tablet or headset can be used for digital image correlation and change detection. All of the necessary procedures and forms can be brought to each location digitally and updated on site. Integrated tools such as the extender stick with belt camera and laser rangefinder are essential to monitoring. Data and voice communications with a base station or remote sites can be accomplished using 4G LTE or 5G cellular. WISE-BACK™ greatly reduces the process time between data collection and final inspection report generation.

Operator and System Engineer Rounds

Situation: Nuclear plant operators and system engineers conduct inspection walkdowns (“rounds”) of plant equipment on a periodic basis. They monitor equipment condition and performance, ensure maintenance is performed, respond to abnormalities, determine causes, and fix issues. The task requires keen observation, plant knowledge and discipline.

Solution: WISE-BACK™ enhances the ability of an operator or system engineer to record observations backed up by images and video. It provides access to plant documents—checklists, procedures, specifications and drawings—as well as data analysis and trending tools. The operator or system engineer has direct, hands-free contact with the Control Room or SME. WISE-BACK™ increases the likelihood of detecting, analyzing and addressing equipment issues, thereby maximizing plant reliability and performance.

Maintenance

Situation: Maintenance personnel performing an activity may be limited by tight working spaces. Even the process of inserting and extracting personnel in these spaces can be difficult and time consuming.

Solution: The tool belt holds a number of integrated tools with flexibility in the types of tools carried into a work zone for a specific application. The headset allows a remote person to see exactly what the user is seeing in real time. The remote person can provide guidance, review and peer checking without entering the work location.

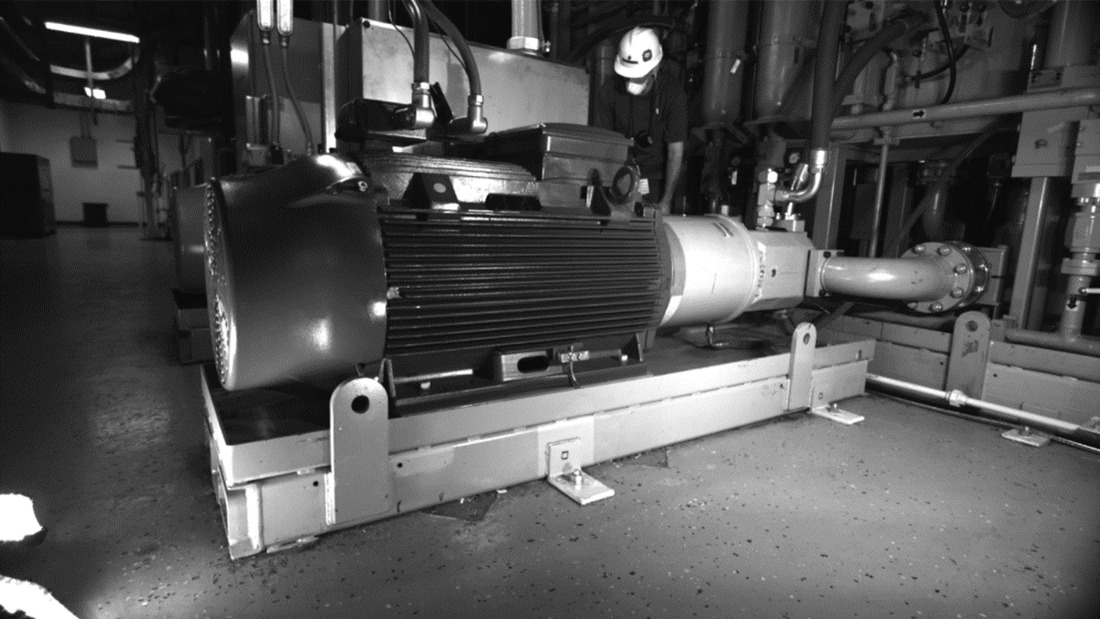

Non-Contact Vibration Monitoring

Situation: Documentation of pump characteristics and operating parameters is critical to condition assessment. To capture vibration data of a malfunctioning pump, engineers can utilize a non-contact camera system. In order to properly collect and analyze data, the appropriate procedure must be followed, and field observations should be reported.

Solution: WISE-BACK™ enables the engineers to enter the monitoring camera system parameters hands-free via voice command while focusing on the task at hand of capturing vibration data from the pump. The engineers can check off each step of the installation procedure via voice command, then use the headset and camera to take photographs of the installed system and pump configuration for the final report. During the test, site engineers and technicians can reach out to remote experts to provide real-time condition assessment and determine if further analysis is required.

Turbine Blade Measurements

Situation: Low pressure turbine stationary blades are periodically inspected to determine the extent of weld undercutting on the blade attached to the carbon steel base ring. A special tool (the Weld Undercut Profiler) was developed by LPI for the project to assist in these measurements and quickly assess the undercut weld profile of a blade. Each blade is required to be tested individually and measurements must be documented.

Solution: The hard-hat camera provides documentation and verification of the weld undercut profiler measurements. Screen sharing can be utilized to monitor proper field technique of measuring instruments such as the Weld Undercut Profiler in real time from outside the plant. To track numerous tasks, inspection checklists can be viewed and updated using voice commands which reduces the amount of equipment brought to the site and ensures all necessary measurements are completed. Photographic images and videos are transmitted to offsite data storage using the plant Wi-Fi network.

Incident Scene Analysis

Situation: Proper inspection, organization, and documentation of failed components such as piping is critical especially right after an incident. Using traditional investigation tools—paper, cameras, measuring tools—requires time on the back end to consolidate data and produce final documents. Inspection and data collection of the incident scene by various personnel and elapsed time become problematic during later documentation.

Solution: WISE-BACK™ enables onsite incident investigators to document, photograph, record measurements quickly and effectively. Data is automatically stored on a secure server where other team members not at the incident scene can review. The onsite investigator can reach out to remote experts to provide real-time review or guidance.

Weld Inspection

Situation: Visual inspection of welds can detect a variety of surface flaws, including cracks, porosity and unfilled craters, regardless of subsequent inspection procedures. Dimensional variances, warpage and appearance flaws, as well as weld size characteristics, can be evaluated. Documentation of the visual inspection with photography and annotations is advantageous to serve as objective evidence and later reference.

Solution: WISE-BACK™ provides an integrated platform for documentation of the weld visual inspection using appropriate measuring tools. The integrated camera and voice command capabilities allow for rapid documentation of annotated photographs providing objective evidence of the inspection. The inspection is automatically stored in a secure cloud server for access and verification by appropriate stakeholders.

Manhole Inspections

Situation: Periodic inspections of municipal manholes require entering confined, low light workspaces. The difficult working conditions present challenges to traditional field data collection techniques. Components in the manholes are subject to different inspection intervals. Tracking inspections of individual components is critical to maintain integrity, reliability and compliance.

Solution: The hands-free operation of WISE-BACK™, via voice commands allows for increased maneuverability in confined spaces as there is no need for a clipboard or other handheld data collection devices. The integrated voice activated flashlight illuminates the scene at eye level for added safety. Furthermore, WISE-BACK™ allows for the assignment of individual tasks and provides Preparer-Checker-Approver accountability steps to ensure data is collected and accurate. Electronic data storage with associated photographs allows for tracking and trending, future data mining and on-the-fly adverse condition work order generation.

Work Activities in Radiation and Contaminated Areas

Situation: Nuclear plant workers have to perform inspection and maintenance activities in radiation and contaminated areas. To limit worker dose and the generation of radioactive waste, it is advantageous to perform activities as expeditiously as possible with only tools needed for the activity.

Solution: The head-set enables data to be entered into forms handsfree, greatly assisting in the gathering of data for workers wearing protective clothing. The ability for third-arty remote verification of activities limits the number of workers needed to enter the radiation area reducing accumulated worker dose. The assistance of remote experts can be called-upon by the worker helping answer or troubleshooting unforeseen issues without the need for an additional entry into the radiation area, thus greatly assisting the work activities to meet ALARA goals.

Fabrication Shop Verification

Situation: During the rapid fabrication and production of bespoke components that are part of a larger assembly being fabricated across multiple locations, verifying dimensions and manufacturing tolerances is critical for proper fit and function.

Solution: WISE-BACK™ provides multiple ways to rapidly communicate critical information. Engineering documentation can be pre-loaded or remotely uploaded to WISE-BACK™ users for quick field reference. If the documentation requires clarification, remote guidance can be employed by voice or text chat with base station personnel to determine the proper path forward. Additionally, the base station can see a live view of the field conditions through the camera to accurately assess the situation.

Switchyard and Substation Inspections

Situation: Electrical substations and switchyards require periodic inspections to verify the health of the equipment. Visual inspection is the primary tool. Condition checks (on-line/off-line) also help to identify abnormalities and required condition-based maintenance. Inspections are often a challenge due to the number and variety of components to be inspected. Remote locations, local environmental conditions and hard to access components all add to the difficulty.

Solution: Integrated cameras have zooming capability to view buses and overhead equipment. They can be augmented with specialized cameras such as FLIR to obtain thermal profiles. Checklists and inspection forms can be filled out by voice control. Electrical diagrams, drawings, specifications and manuals for all of the equipment as well as past inspection records can be accessed via data hotspots over cellular or digital mobile radio.

Energy Audits

Situation: Many municipalities require that new buildings incorporate energy efficiency measures in their designs. In addition, performance must be monitored over the life of the building. To meet these requirements, building owners conduct continuous energy audits of building envelopes, mechanical systems, and electrical systems to gauge energy consumption.

Solution: By their nature, audits are always performed away from the home office. WISE-BACK™ allows an auditor to carry an entire suite of tools and sensors on the tool belt. With WISE-BACK™, the user can:

- Connect and communicate with remote experts

- Use integrated specialized sensors, such as FLIR and flowmeters

- Consult documents in the home office, from building drawings to equipment specifications to building and energy codes.

- Complete audit reports with integrated and annotated media while at the job site